Solar modules are marvellously complex structures. Every module contains many intricately engineered solar cells that are connected electrically. This bond between cells allows the forward flow of current.

But what happens when this flow gets disrupted? When one or more cells in a string, are unable to produce enough current? Situations such as these give rise to what is known as the hotspot effect, which can be a fire hazard.

What are Hotspots in Solar Panels?

Suppose a cell in the module becomes shaded or soiled. Because the cells are in a series connection, the shaded cells start acting as a resistance and block the forward flow of current. As a result, the weak cells manage to bring down the energy output of the entire string.

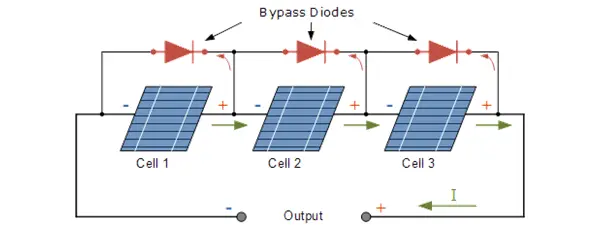

To counter such scenarios, manufacturers install bypass diodes in the solar panels. When the weak cell hinders the flow of current, the diodes get activated to provide it with an alternate route.

But diodes are not permanent solutions.

Consider this image below:

Source: Renewable and Sustainable Energy Reviews

The last cell in the series is shaded. In the absence or failure of a diode, the poor cell will start consuming energy instead of generating it. Acting as a load, it will begin taking power from its neighbouring cells.

The dissipation of power from the good cells to the poor cells is called reverse bias, which ultimately leads to overheating. This creates a hotspot effect.

Hotspots can lead to major consequences.

To begin with, hotspots on solar panels will bring down your power output. The difference in the generation might not stand out in the short run. But in the long run, the same minor difference can turn into a significant power loss.

And the problems don’t end here.

A study conducted in the United States analysed PV modules that had been running for 1-3 years, to find the reasons behind module failures and degradation. Out of the 115 modules observed, 22% failed due to hotspots.

If a hotspot is not mitigated, the overheating can lead to glass breaking, melting of the sheets underneath the panels, degradation of the solar cells, and in extreme scenarios- fire.

What do Hotspots Look Like?

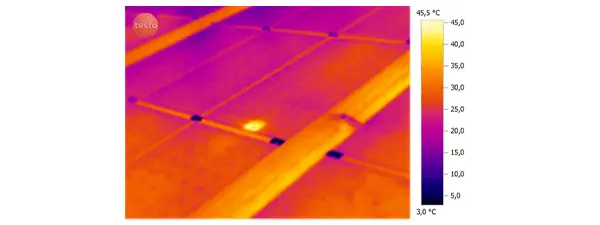

Sometimes hotspots appear as brown spots or noticeable damage on the surface of the panels. But most of the time, hotspots are not visible to the naked eye.

But if you cannot see it, it doesn’t mean that it’s not there!

The best way to detect hotspots is through thermography, which highlights the overheated spots.

But since most consumers do not have access to this equipment, how do they know there is a problem brewing?

This is why one needs to constantly monitor the energy output of each panel, and be on the lookout for any fluctuations in the generation.

What Causes Hotspots?

2. Soiling: Bird droppings, dirt, mud accumulated on the corners of panels, etc.

3. Module Damage: Damage such as broken glass, bent frames, micro-cracks, etc. incurred during manufacturing, transportation, or installation.

4. Internal Design defects: The selection of poor-quality components and faulty production can cause defective solder joints, defects in the PV cells, etc.

5. External factors– Damages caused by weather conditions such as snow, hail, lightning, extreme heat, or cold temperatures.

How Can Hotspots be Prevented?

In many cases, the damage from hotspots is severe enough to necessitate the replacement of panels.

Fortunately, hotspots can be prevented and their effects reduced. Here’s how:

1. Testing the Location

A thorough study of the location before the installations is crucial.

It will allow installers to spot any obstructions, such as vegetation, trees, water tanks, electrical poles, etc. which might cast shadows on the panels. In cases where shading cannot be avoided, module-level smart electronics can be used. These devices extract the maximum yield and improve the performance of the PV system in conditions such as shading.

A detailed study will also help the developers understand the types of weather conditions witnessed by the area. Some locations are prone to extreme climate (frequent lightning storms, hailstorms, or snow). Here, the installers can recommend the type of modules that have been extensively tested under such conditions.

2. Regular Maintenance

A soiled panel will not only reduce the power output but also increase the risk of hotspots. Thus, it is crucial to clean the panels once every two weeks. Ensure that it remains free of leaves, debris, and bird droppings.

At times water gets accumulated at the corners of the panels, and leaves behind a layer of dirt. This type of soiling can generate hotspots and lead to serious problems in the future. To tackle this issue, you can utilize a water drainage clip such as Aqua Pi.

The device, which gets attached to the lower edge of the panel, automatically drains accumulated water and significantly reduces the chance of a hotspot.

3. Efficiently Designed Panels

Invest in high-quality panels that consider the possibility of shading or soiling and incorporate hotspot control technology such as bypass diodes into their designs.

For example- the global solar panel brand, Canadian Solar, manufactures panels with a half-cut cell design and optimizes the number of cells protected by a single diode. These designs choices lower the hotspot temperature and mitigate its risk.

While you explore solar systems, always look for efficiently designed panels with better shading tolerance and lower hotspot temperature.

4. Allow Air Flow Underneath Modules

Power generation in solar PV systems is indirectly proportional to the panel’s temperature. In extreme heat, a solar plant’s energy output goes down.

Since hotspots develop because of overheating, proper ventilation and good airflow are important in solar systems. In rooftop installations, one must ensure that there is enough space between and underneath panels.

With industrial solar systems, panels are mostly installed on sheet roofing, which absorbs heat much faster. This is why one must always ensure that there is proper distance between the tin shed and the panels. By leaving space for air circulation, heat pockets can be avoided which significantly reduces the effects of hotspots.

To avoid the possibility of solar panels heating up, one can also invest in building integrated solar systems like Ornate InRoof. The structure functions as a primary roof allowing airflow underneath and generating higher amounts of energy.

5. Full Site Inspection After Installation

We have established that rough handling of modules during transportation or installation, can lead to internal damage. In the future, these small dents, scratches, or microcracks can turn into major problems.

Hence, a full site inspection becomes necessary. Electroluminescence imaging (EL), along with thermography allows developers to check for any risk factors.

About Ornate Solar

By partnering with the best-in-class solar panel and inverter brands from around the globe, Ornate Solar has made the shift to solar energy, cost-effective, reliable, and easy. We also provide a one-stop shop for top-quality solar accessories, that can be customized as per your requirements.

If you are exploring solar energy systems for your business, reach out to us at 011 4353 6666 to discuss your options.

Leave A Comment