India’s solar journey is moving beyond installations and capacity additions. Today, the focus has shifted to how efficiently solar plants perform in real operating conditions—especially under high temperatures, weak grids, and strict regulatory requirements. This shift is particularly visible in PM-KUSUM and large-scale ground-mounted solar projects, where reliability and actual energy delivery matter more than datasheet claims.

In this environment, inverter selection has become one of the most critical decisions in project design. The inverter is no longer just a power conversion device. It directly influences plant sizing, annual energy yield, grid compliance, and long-term project economics.

This is where Hopewind is emerging as a serious technology choice—not because of marketing promises, but because of proven on-site performance.

In this blog, we explore how Hopewind stands apart from conventional string inverters, why it’s ideal for KUSUM projects, and what the real data from live installations tells us.

Why Real Performance Matters More Than Ratings

Most inverters look impressive on paper. However, once deployed on Indian sites, many struggle to deliver their rated output consistently. High ambient temperatures, voltage fluctuations, and mandatory reactive power support often force inverters to reduce active power output.

These reductions are rarely obvious at first glance. They don’t appear as alarms or failures. Instead, they show up quietly as a lost generation over months and years.

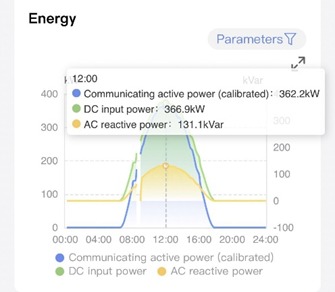

At our KUSUM site, the Hopewind inverter behaved differently.

The inverter was observed converting 366 kW of DC input into 362 kW of active AC output, while simultaneously delivering 131 kVAr of reactive power. This resulted in the inverter achieving its full 385 kVA output, without any external reactive power equipment.

This is a crucial distinction.

In many conventional inverters, once reactive power is introduced, active power is immediately compromised. External devices such as SVGs are often required, increasing system complexity and cost. Hopewind manages this internally, maintaining stable performance while simplifying plant design.

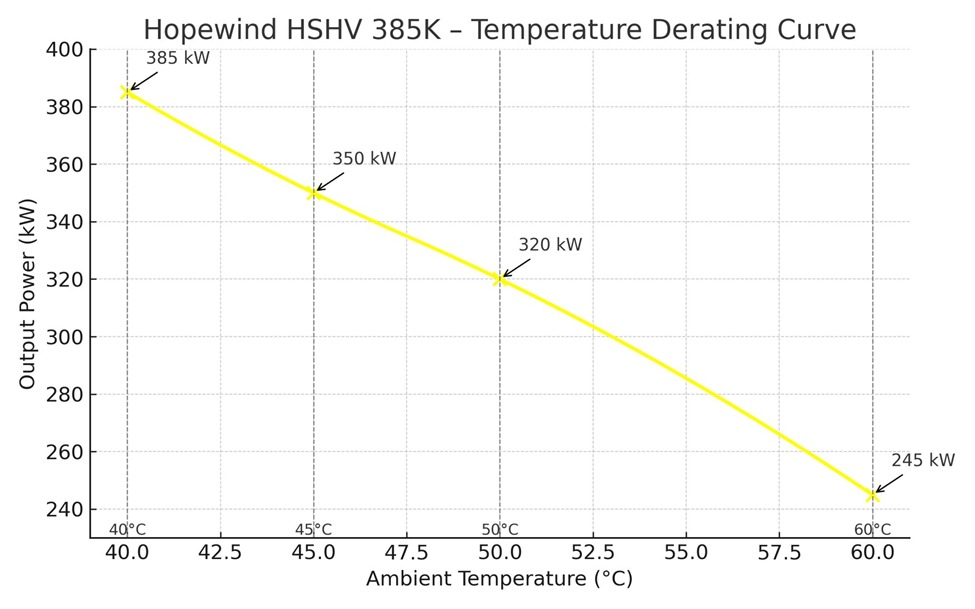

Thermal Behaviour Designed for Indian Conditions

India’s solar plants rarely operate at standard test conditions. Most sites experience ambient temperatures between 35°C and 45°C for a significant part of the year, especially in KUSUM-heavy regions.

This is where inverter thermal behaviour becomes critical.

The Hopewind solar inverter demonstrates:

- No derating up to 40°C

- Approximately 350 kW output at 45°C

- Approximately 320 kW output at 50°C

In contrast, many competing inverters begin derating much earlier—often around 30–35°C—and drop to 275–295 kW at 50°C. When reactive power obligations are added, the usable active power can fall even further.

These losses occur precisely during peak irradiance hours, when the plant should be generating the most energy.

Hopewind’s advanced thermal design and SiC-based power electronics allow it to operate stably at elevated temperatures, preserving generation when it matters most.

Why This Changes Plant Sizing Strategy

Traditional inverter sizing is often driven by worst-case temperature assumptions, typically around 50°C. While this is a valid design consideration, it ignores how plants actually operate for most of the year.

If an inverter can deliver near-full power up to 40°C and maintain strong output even beyond that, conservative sizing starts to work against the project instead of protecting it.

Hopewind’s performance encourages a more realistic sizing approach:

- Higher inverter utilisation

- Reduced inverter count

- Better DC-to-AC optimisation

For developers, this means less equipment for the same capacity, simpler layouts, and improved long-term returns.

A Natural Fit for CdTe-Based Solar Plants

CdTe thin-film modules are increasingly adopted in high-temperature regions due to their superior thermal behaviour. Their wider bandgap results in lower voltage loss as temperature rises, allowing them to maintain more stable power output during peak midday conditions.

However, this advantage is often neutralised by conventional inverters that begin derating early.

Hopewind’s thermal behaviour closely aligns with CdTe characteristics. The inverter supports mandatory anti-PID operation through controlled negative bias and continuously logs this data—an essential requirement for long-term reliability and warranty compliance.

In CdTe-based systems, this alignment ensures that the module’s thermal advantage translates into real energy retention, rather than being lost at the inverter level.

CdTe modules are built to tolerate heat.

Hopewind is built to operate in it.

Rethinking the 50°C Assumption

A common industry practice is to size inverters assuming continuous operation at 50°C. In reality, most Indian sites spend the majority of the year below this threshold.

When inverters derate aggressively at moderate temperatures, plants end up being sized for conditions that occur only for a limited period—while sacrificing generation for the rest of the year.

Hopewind challenges this logic.

If an inverter can deliver 350–370 kW for most of the operating year, why should plants be sized around 275–300 kW? This question goes beyond theory; it directly impacts:

- Annual energy yield

- Inverter count

- BOS cost

- O&M complexity

By maintaining output at real operating temperatures, the Hopewind inverter helps unlock generation that would otherwise remain untapped.

Impact at the Plant Level

The difference becomes clearer when viewed at scale.

In a 5 MW AC / 6.5 MWp DC plant:

- Hopewind 385 kW inverters typically require 15–16 units

- Conventional 350 kW-class inverters often require 17–18 units

That’s 2–3 fewer inverters—which means fewer foundations, fewer cables, fewer auxiliary systems, and fewer points of failure.

Over the lifetime of the plant, this translates into:

- Lower capital expenditure

- Easier installation

- Reduced maintenance effort

- Higher cumulative energy generation

Across larger projects, these benefits multiply significantly.

Why EPCs and Developers Are Taking Notice

Hopewind’s growing adoption in PM KUSUM and large-scale projects is driven by observed performance, not theoretical advantages.

What EPCs are seeing on-site is:

- Stable output at high temperatures

- Internal handling of reactive power

- Predictable behaviour across seasons

- Minimal compromise during peak generation hours

Winter brings additional generation headroom. Summer brings stability instead of sharp derating. Across the year, the inverter behaves consistently—exactly what long-term projects demand.

Why Hopewind Inverter Is Worth Considering

Inverter technology is no longer just about rating. It’s about real output, reliability, and long-term energy yield. Hopewind’s proven performance at KUSUM and large-scale projects ensures that developers and EPCs get the power they expect, when they expect it.

If you’re planning your next KUSUM or utility-scale solar installation, choosing the right inverter can make a significant difference in energy production, plant design, and long-term returns.

About Ornate Solar

Ornate Solar is a leading solar company with 10 years of experience in the industry and the mission to reimagine the way solar is installed worldwide.

By not only partnering with the best-in-class solar brands but also developing our high-quality solutions (panels, solar inverters, accessories, InRoof), we develop and deliver solutions that are modern, reliable, and effective.

Ornate Solar is also a trusted BESS manufacturer in India. We have developed UnityESS, an advanced energy storage solution to provide reliable power and energy independence.

If you are looking for high-quality solar solutions, call us at 1800 2026 252 to discuss your options.

Leave A Comment