The textile industry or clothing sector in India accounts for about 4% of the global market. In terms of output, foreign exchange profits, and employment, India’s textile industry is one of the largest and most important industries in the world.

The textile industry is also energy-intensive. Energy costs might account for up to a quarter of the entire operating costs. In general, electricity is used in the textile industry to power machinery, cooling and temperature control systems, lighting, office equipment, and so on; oil is utilized as a fuel for steam boilers; liquefied petroleum gas; coal; and city gas.

In recent years, we have seen a growing number of textile companies adopting renewable resources such as wind and solar as alternate sources of energy, with the textile industry in Tamil Nadu being among the first in the country to do so.

Why Textile Industry Should Go Solar:

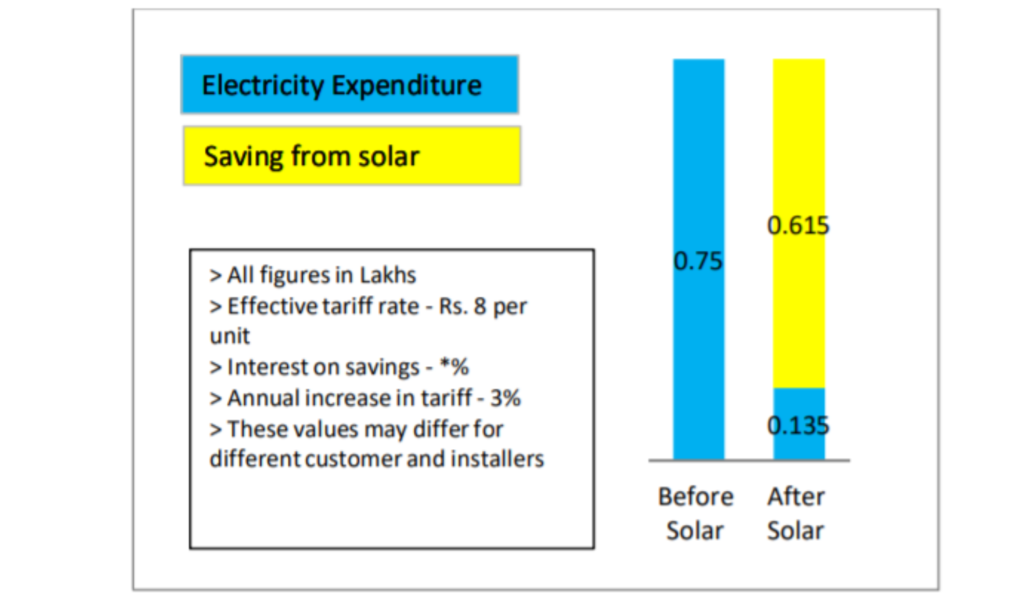

- Cost reduction – The electricity tariff for industrial consumers is the highest among all sectors, and for industrial consumers, in most states, solar will be cheaper. Solar prices are going to remain almost the same throughout the lifetime of the solar plant (except for degradation and some replacement) whereas the electricity rates from conventional sources of power are expected to escalate year on year.

- Compliance with Renewable Purchase Obligations (RPO) – Several industrial consumers of electricity have to meet their RPO and setting up a solar plant is one of the simplest ways to comply with the RPO.

- Availability of roof space – Unlike most commercial establishments, most textile factories have vast unshaded roof areas and vast tracts of unused land. Setting up solar plants on these unshaded and unused areas is a relatively easy task.

- Energy Savings – Solar power generated at the site can offset the electricity that needs to be drawn from the grid and reduce the reliance on diesel gensets. This in turn leads to further cost reduction.

- Reducing carbon footprint – Solar plants help in environmental protection and also reduce carbon footprint.

Understanding Through an Example

Let’s suppose, a textile factory has installed a solar PV system:

| Sample System Details | |

|---|---|

| System Size | 5 KW |

| Rooftop area (Shadow free roof top area needed ) | 500 sq. ft |

| Average Units Per Month | 625 KWH |

| Operating life time of panels | 25 Years |

| Cost-Benefit Analysis | |

|---|---|

| Approx. System Cost | ₹ 3,75,000 |

| Accelerated Depreciation Benefit | ₹ 1,02,000 |

| Effective System Cost | ₹ 2,73,000 |

| 1st year Saving Without Interest | ₹ 61,000 |

| Payback Period (after including interest on Savings) | 3.3 years |

| 10 years rate of Interest IRR | 29% |

During the day, the solar PV system synchronizes with the power grid and supplies energy for captive consumption. In the event of a power outage, the Solar system synchronizes with the Diesel Generator to deliver up to 65% of the energy needed to keep the business running.

Solar Installations in Textile Industry

| Name (Textile Industry) | City | Capacity (in kW) |

|---|---|---|

| Shyam Cotton | Rajkot | 400 |

| Bhumi Fashion Pvt Ltd | Surat | 80 |

| Sears Knitwear | Ludhiana | 100 |

| VPS Textiles India Pvt Ltd | Coimbatore | 297 |

| Prem Textiles International Pvt. Ltd | Indore | 267.3 |

The Verdict

The energy-intensive textile industry can benefit immensely from going solar. Using a clean source of energy will not only bring down the operational cost of a company but also help reduce its carbon

footprint.

Also Read

How Can We Help?

Ornate Solar is a leading solar company with 10 years of experience in the industry and the mission to reimagine the way solar is installed worldwide.

From advanced solar panels, innovative inverter solutions, and high-quality accessories to the unique InRoof that turns panels into the primary roof, we develop and deliver solutions that are modern, reliable, and effective.

Ornate Solar is also a trusted BESS manufacturer company in India. We have developed UnityESS, an advanced energy storage solution to provide reliable power and energy independence.

If you are exploring solar solutions for your clothing factory, reach out to us at 1800 2026 252 to discuss your options.

It is a matter of learning and knowing. It is a matter of everyone’s work

Absolutely! Switching to solar energy in the textile industry is a smart move for several reasons. First, it reduces energy costs significantly, helping textile factories save money. Second, it aligns with sustainability goals, reducing the carbon footprint. Third, it ensures a more stable energy supply, reducing dependence on conventional sources. Fourth, it can lead to government incentives and tax benefits. Finally, it sets a positive example for other industries to follow. Kudos to the textile industry in Tamil Nadu for leading the way in adopting renewable energy sources like solar!

How do we calculate the power required by all our machines in the textile mill for going completely solar?

Sir, you can verify your approved load through your authorized Discom or compute your maximum demand from your electricity bills.

For further queries, you can contact us on +91-11-4353-6666 and info@ornatesolar.com or you can share your contact details here and our team will reach out to you.

Can we also go solar for automobile garage and service centers. i mean for the jack and lift ramps?