Half-Cut Solar Panels

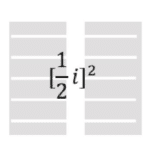

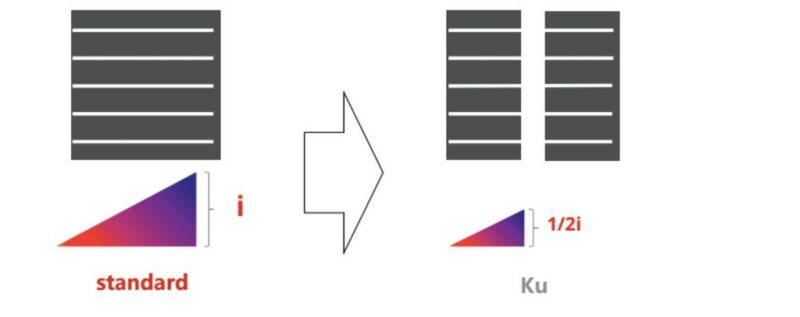

Explaining what half-cut solar cells are doesn’t involve complex scientific explanations involving quantum mechanics. They are normal solar cells that have been cut in half. Instead of having 60 solar cells, as most panels put on roofs do, they have 120 half-sized ones. This results in lower electrical resistance that improves efficiency. An additional benefit is half cut panels resist the effects of shade better than standard solar panels. This isn’t directly due to the cells being cut in half but because of the way they are wired together.

WHY SOLAR CELLS ARE CUT IN HALF?

Solar cells are cut in half to reduce the cell to-module losses during assembly. Power loss is generally proportional to the square of the current times resistance. Therefore when cutting a solar cell in half, the power losses are reduced by a factor of four.

TECHNOLOGY HIGHLIGHTS

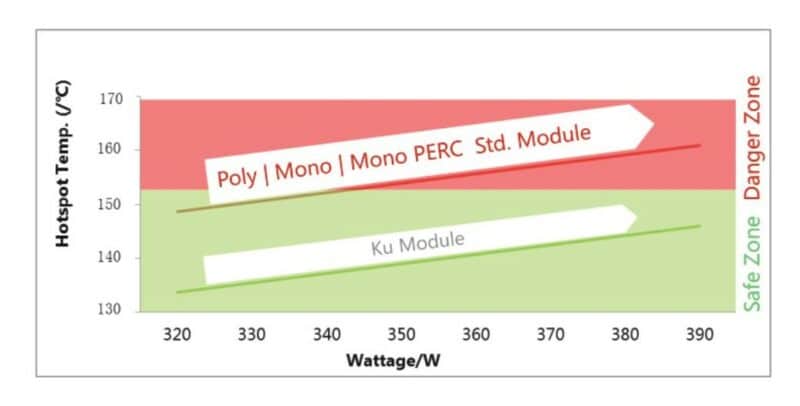

Dual cell technology ensures lower module operating temperature and lowers hot spot temperature.

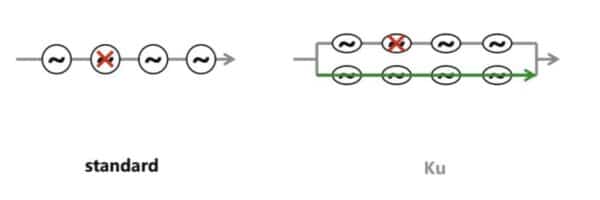

Matrix interconnection provides higher failure tolerance.

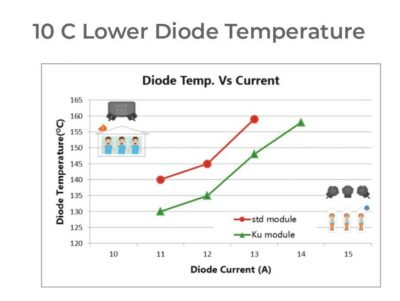

Micro J-Box design reduces diode temperature by 10C, improving reliability.

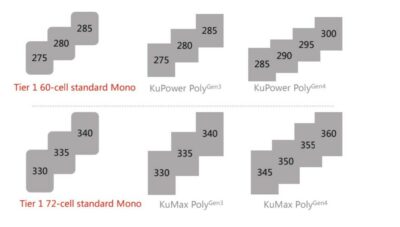

BENEFITS HIGHER POWER

Module Output Power Improved by 4%

Internal power loss reduced by: 75%

Module power output increased by: 4%

Wattage Matches Tier 1 Standard Mono Products

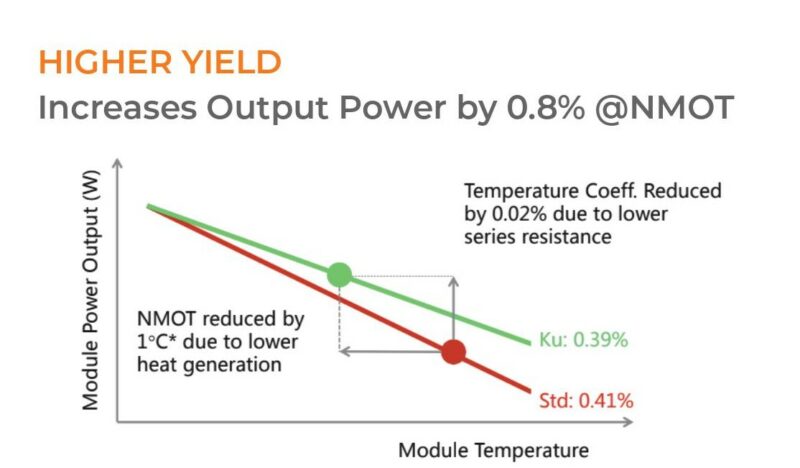

HIGHER YIELD

Increases Output Power by 0.8% @NMOT

Ideal for Hot and Sunny Regions

The advantage of Ku module of a relatively lower operating temperature is bigger in hotter and Sunny environment

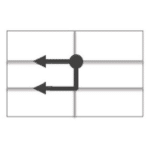

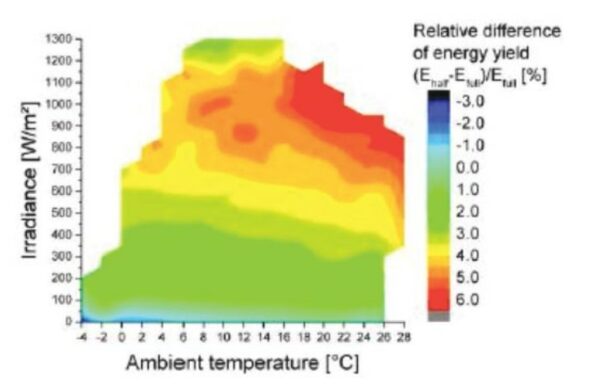

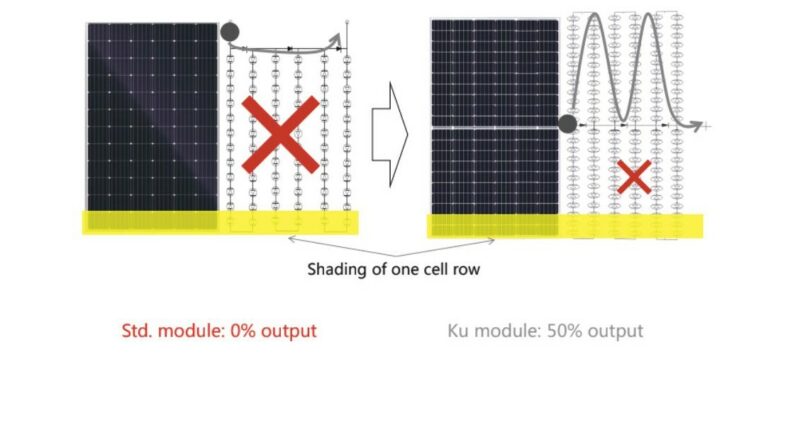

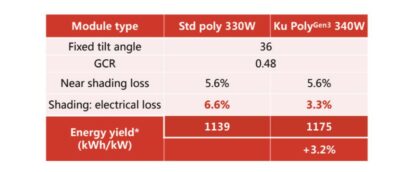

BATTER SHADING TOLERANCE

Maintain 50% Power Output with up to 50% Shading

Generate 3.2% More Electricity for a Land Constraint PV Plant

LOWER RISK

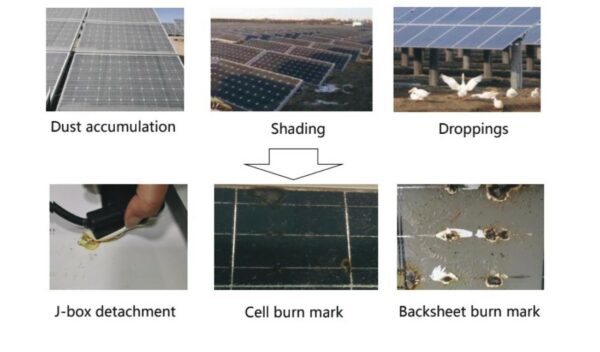

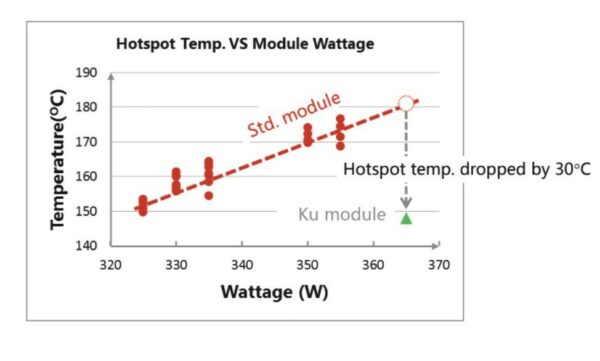

Cause and Impact of Hotspot

Hotspot Temperature reduced by 30 OC

Ku Module Always Operates in Safe Zone

LOWER RISK

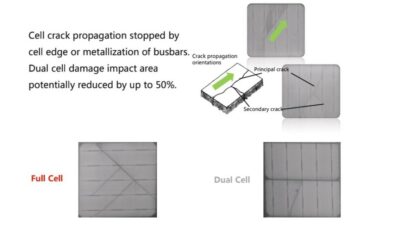

50% Lower Micro-crack Risk

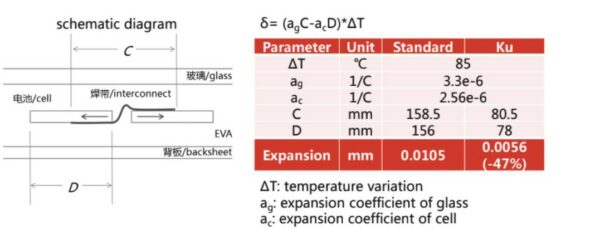

50% Reduction of Soldering Joint Stress

The thermo-mechanical stresses on interconnects and cell soldering joint decrease by 50% due to shorten cell and interconnect length, therefore the microcrack and soldering joint issues are greatly minimized during module operation

10 C Lower Diode Temperature

Improvement of Failure Redundancy

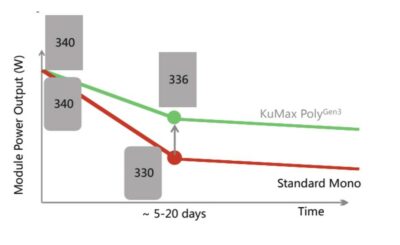

LLOWER LID

Ku PolyGen3 Power output improvement of up to 2% after LID

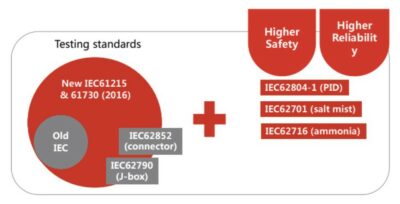

BEST-IN-CLASS CERTIFICATION COVERAGE

CUSTOM DESIGNED SOLAR ENERGY SYSTEMS

Canadian Solar provides high quality solar panels with half-cut solar technology which provide the higher efficiency. At Ornate Solar our goal is to design the perfect solar system for you. This includes equipment type, panel placement, number of panels, and inverter type. We design your system to ensure it produces the most energy possible at the lowest rates available. To get the best prices of the Canadian Solar Panels/ Modules series (HiKu MONO, HiKu Series, KuMax Series). We are the exclusive official partner of Canadian Solar panels in India.

For more information, please give us a call at 011 4353 6666.

Excellent panels