Are you looking into getting your industrial roof repaired or replaced?

Perhaps your metal roof is starting to rust in certain areas, leading to water leaks that are damaging your property. You may even be concerned that the solar structure is on the verge of collapsing. Or maybe you’re considering installing solar panels but want to take care of roof repairs beforehand.

Whatever the reason, if you’re thinking of removing or replacing your old sheet roof, consider upgrading to a solar roof instead. Not only does it solve your roofing issues, but it also turns your roof into an energy-generating asset, making it a smarter and more sustainable investment for the future.

The Drawbacks of Sheet Roofing

Metal roofs are lightweight, durable, and affordable. Such factors make them a popular roofing choice for industrial units. Though this type of roofing looks attractive in the short run, it can be prone to issues in the long term. This especially holds if you hope to install a rooftop solar plant in the future.

1. Leakage Issues

One of the most common problems businesses face with sheet roofing is leakage. Roof leaks can develop due to misaligned roof screws, corrosion, lack of proper sealing at the overlapping spots, etc.

The water that seeps through can be disastrous for the equipment, machinery, and stock. If water comes into contact with the electrical wires, this seemingly small issue can develop into a much greater safety risk.

One can opt for waterproofing, but it will be an additional expense.

2. Prone to Rusting

Be it steel, aluminum, or tin, when sheet roofing comes in contact with moisture, it begins to rust. There are protective coatings available to prevent this problem, but their effectiveness eventually subsides with time.

Galvanic corrosion is another type of deterioration associated with these roofs. It happens when different metal types interact in the presence of elements like rainwater.

3. Overheating

Metal roofs can overheat, which turns the interior of the building stuffy and warm. High temperatures can also become a major impediment if you install solar panels on top.

The amount of energy a solar panel generates is inversely proportional to the temperature of that module. If a panel gets too hot, your generation goes down. If an adequate gap between the solar panels and the sheet roof is not provided and they get too hot, the energy generation will go down.

4. High Roof Repair Cost

Metal roofs are not easy to repair. In case of serious damage, like corrosion or cracks and dents, the entire roof has to be replaced. This process is time-consuming and costly.

Further, if solar panels have been installed over the roof, one will have to remove and reinstall the entire system before starting on the repairs. The process adds to the maintenance cost.

5. Not Sustainable

Corrugated sheets are a popular choice for industrial factories and sheds. You can recognize them through their distinctive folds design. Even though they look good, their manufacturing process can be notoriously unsustainable.

Approximately 1.85 tons of carbon dioxide is emitted to produce one ton of steel sheet.

The Solution

We now know that metal sheets are less than ideal roofing material. Then what is the alternative? Ornate InRoof – India’s first integrated Solar Roof solution is your answer.

Installing solar power systems is a great way to generate clean energy and reduce electricity costs. You can also take care of your roofing needs through an integrated InRoof. The great news is that one can install a solar roof without damaging or removing the steel building structure under the previous roof.

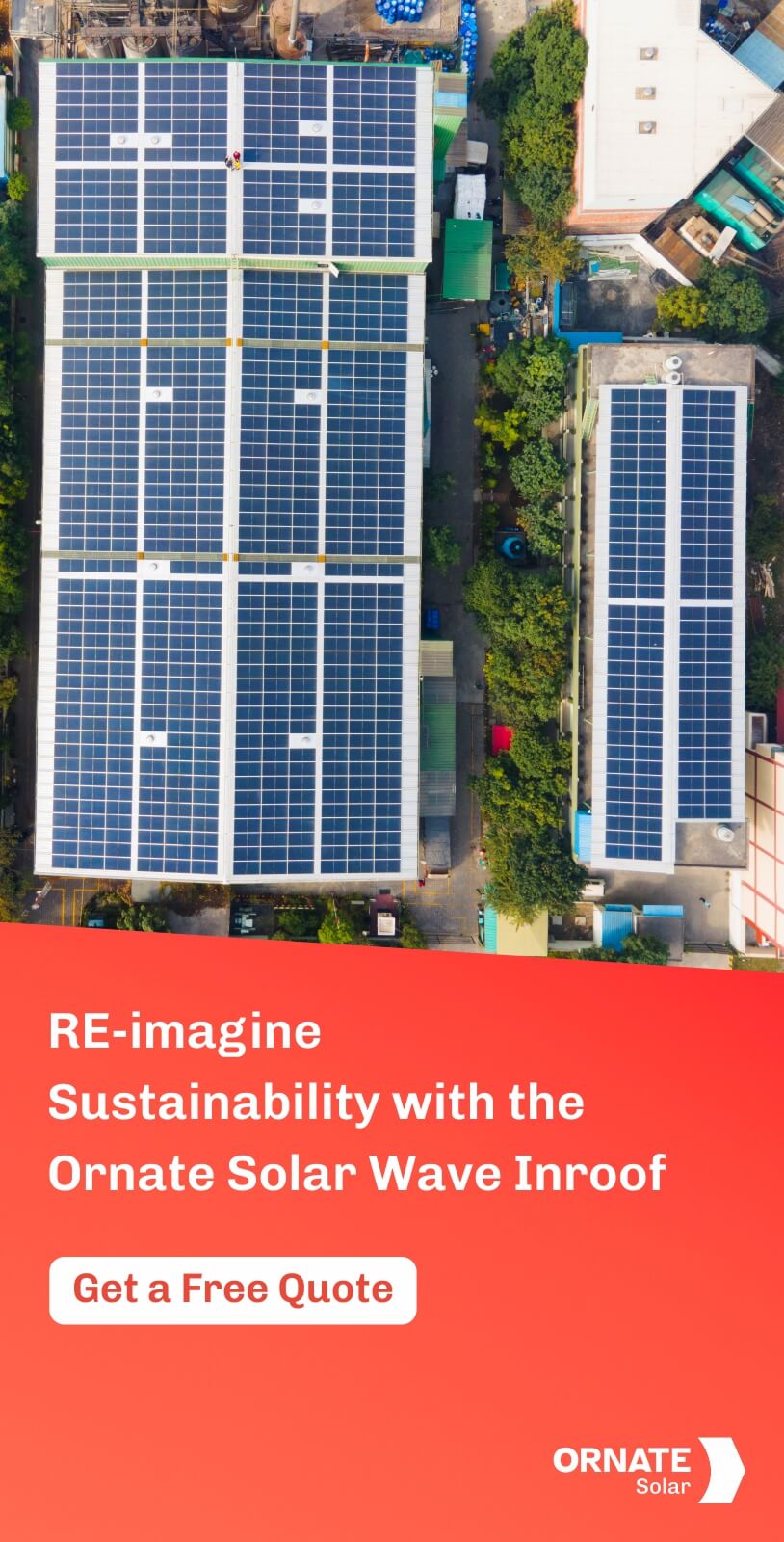

Ornate InRoof- An Integrated Solar Roofing Solution

By integrating the panels into the roof itself, Ornate InRoof provides a unique solar solution. The structure that accommodates 26% more panels in the same area, not only generates energy but also functions as the primary roof for the building.

Here’s how InRoof overcomes the challenges of sheet roofing and offers a better alternative.

1. Cost-Effective

Traditional solar panel installations place panels on mounting structures drilled into the roof. Since the InRoof structure works as the roof itself, it eliminates the need for sheet-roofing, thereby saving the cost of metal roofing and mounting structures.

A double layer of leak protection in the InRoof system ensures 100% safety against water ingress. The first layer is an aluminum top cover that prevents water from getting inside the shed. The second layer is a galvalume MG shield that redirects the water to the gutters at the corners. This water is moved down through a pipe system.

3. Corrosion Proof

InRoof structure is coated with a specially made material that is highly durable and fully rust-resistant. In case certain chemicals are used in the factory, the InRoof is tested against those elements.

For example, the Ornate team recently completed an InRoof installation in Ludhiana for a surface treatment chemicals factory called GEM Technologies. Both the structure and modules were tested against the substances before deployment to ensure safety and durability.

4. Better Area Utilization

In a traditional solar rooftop installation, a 1kW system requires an area of 100-130 sq. ft. But in InRoof, a 1kW installation is completed within an area of 65-70 sq. ft. Thus, solar InRoof accommodates more panels in the same space.

5. Detachable Structure

We established that repairing a roof with solar panels is challenging, as modules are removed to get to the spot underneath. InRoof overcomes this issue through a snap-lock fastener that allows easy attachment and detachment of solar modules.

6. Prevents Overheating

Since there is no metal sheet underneath the panels, the airflow gap is maintained. This prevents the panel from overheating and results in 10% more generation than traditional setups.

Moreover, solar InRoof keeps the interiors a few degree cooler in comparison to metal roofing.

7. Aesthetically Pleasing

Installing solar panels on your roof may affect the look of the building. With InRoof, you have no such problem. As the structure seamlessly integrates solar panels into the roof itself, you get a futuristic and unique-looking roof design that can work well with all types of architecture.

Unlike metal roofs, the solar roof also allows light to pass through them which keeps the interiors bright and vibrant.

8. Customizable

InRoof structure can accommodate all types of solar panels. It can also be customized to suit all roof types, styles, and sizes.

9. More sustainable

Generating clean energy, solar InRoof helps a business lower its carbon footprint. By eliminating the need for sheet roofing, the structure prevents the emissions that would have been released during the manufacturing process.

Recent InRoof Installations

Ornate Solar commissioned a 3.25 MW InRoof for one of the largest steel manufacturers in India- Jindal Steel and Power Limited. Spanning an area of 1,97,000 sq.ft, the massive InRoof system powers JSPL’s new manufacturing facility in Odisha.

Nhava Sheva Port, India’s second-largest container port, is situated along the Arabian Sea in Navi Mumbai, Maharashtra, and is operated by the Jawaharlal Nehru Port Trust Authority (JNPTA). Ornate Solar installed a 641 kW InRoof system across 39,000 sq. ft. at the port, which is expected to generate around 1,100 MWh of clean energy annually

APL Apollo Group, India’s largest steel pipe and tube manufacturer with a 55% market share, has implemented a 1.45 MW InRoof system across 87,000 sq. ft. at its new production facility in Malur, Karnataka. This advanced solar solution is expected to generate around 2,202 MWh of clean energy each year.

With an annual turnover of over ₹2000 crores, B.L Agro has become one of the top FMCG companies in India. Ornate Solar commissioned a 745kW solar InRoof system at BL Agro’s new production facility in Bareilly.

5. Pangaea Natural Stone, Rajasthan | 530 Kw

Pangaea Natural stone is a Canada-based natural stone manufacturing company. Ornate Solar commissioned a 530 kW InRoof system for Pangaea’s 35,000 sq. ft. manufacturing facility in Bagru.

GEM Technologies is one of the leading manufacturers of Metal Surface treatment chemicals for paint-based applications, cold forming, and coil coating. Ornate Solar installed a unique hybridized roof integrated system for the company’s new chemical factory in Ludhiana, Punjab, where solar panels and metal sheets are seamlessly integrated.

Fronius is among the leading worldwide suppliers of solar grid-connected inverters. The company installed an Ornate InRoof system to use their underutilized roof space and turn it into a seating space, which also generates energy.

About Ornate

Ornate Solar is India’s leading solar company with 10 years of experience. We have also launched India’s first integrated Solar Roof– Ornate InRoof.

From the design conceptualized by the R&D team of Ornate Solar to all the components used in the structure, every aspect of InRoof is made in India. We also offer the longest industry warranties for your complete peace of mind.

Ornate Solar is also a trusted BESS manufacturer in India. We have developed Unity ESS, an advanced energy storage solution designed and manufactured in India to provide reliable power and energy independence.

If you are looking for a solar rooftop solution for your business, reach out to discuss your options and get a quote.

For more information, please give us a call at 1800 2026 252.

The article Replacing Your Industrial Roof by Ornate Solar provides helpful information about the advantages of solar roofs for industrial structures. Anyone researching environmentally friendly roofing choices will find it to be a thorough and educational read.

Kindly, quote for 450 sqmt area fully covered industrial shed.

Hello Sushant, thank you for connecting with us. Kindly share your contact details, and our sales representative will help you better.

Also, you can get in touch with us @ 011-4353 6666