India is the world’s second-largest cement consumer. The country is also the world’s second-largest cement producer after China. India’s infrastructure and construction sectors have a lot of room for growth, and the cement industry is likely to profit greatly from it.

The ready availability of raw materials for creating cement, such as limestone and coal, is a crucial aspect that promotes the sector’s expansion.

In this blog, we will know how the cement industry can benefit from incorporating renewable energy sources, particularly solar energy into their power mix.

Energy Consumption in Cement Industry

In India, just a few sectors have been recognized as energy-intensive. Aluminum, cement, fertilizer, iron and steel, glass, and paper are among them.

The cement business is one of the most energy-intensive sectors, and energy expenses make up a considerable portion of overall manufacturing costs (about 30-40%). The cement industry consumes around ten percent of the total energy utilized in the industrial sector on an annual basis.

According to the Cement Manufacturers’ Association, contemporary cement factories require 68-93 units of electrical energy to manufacture a tonne of cement, whereas older facilities use 110-120 units.

To combat growing power prices and supply unpredictability, the cement industry has over 4,000 MW of captive power capacity built, including coal-fired facilities, diesel generator sets, and wind turbines.

Why Go Solar?

Cost savings – The energy rate for industrial users is among the highest of all sectors, and solar will be cheaper for industrial consumers in most states. Also, the consumer’s electricity rate will remain constant throughout the life of the solar plant, while traditional electricity tariffs will continue to rise year after year.

Renewable Purchase Obligations (RPO) Compliance – Several industrial energy customers must fulfil their RPO, and installing a solar plant is one of the simplest methods to do so.

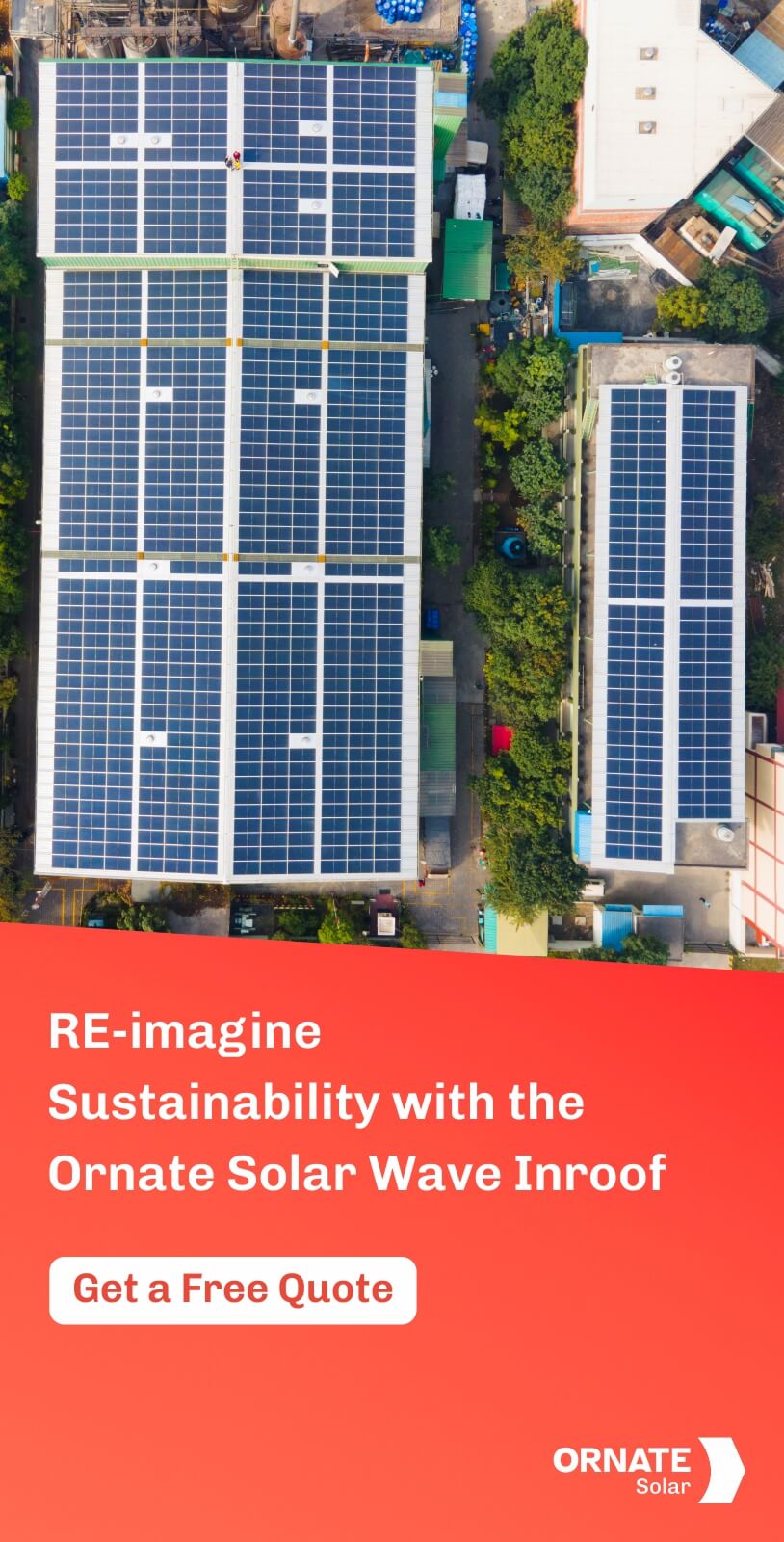

Availability of Roof Space — Unlike most commercial enterprises, most manufacturers feature large expanses of undeveloped land and unshaded roof regions. It is quite simple to install solar plants in these un-shaded and unoccupied locations.

Industrial consumers can also opt for innovative solar solutions like InRoof that turn the solar panel itself into the primary roof, thereby providing better space utilization, energy generation, and aesthetics.

Energy Savings – Solar power generated on-site can help balance the demand for grid electricity and minimize the dependency on diesel generators. This, in turn, leads to even more cost savings.

Carbon Footprint Reduction – The majority of businesses work to reduce their carbon footprint. Solar power plants assist to safeguard the environment while also lowering carbon emissions.

How Installing a Solar Plant Can Help

According to an IFC report, this is how a solar power plant can help meet the power demand of a generic cement plant.

• Generic cement plant, 2 million tons p.a. facility

• Power needs: 25-30 MW

• Power consumption 198 GWh/year

• Land requirements: 20-30 ha

After Installing the solar plant:

• Electricity production from Solar: 18-24 GWh/year or 9-12% of total power needs

• CO2 emission avoided: 15,000-20,000 p.a.

• Estimated Payback period: 4-5 years

Why Cement Plants Should Consider Battery Energy Storage

While solar power can significantly offset grid electricity usage and reduce costs, industrial facilities like cement plants operate 24/7 and often face fluctuating power demand. Solar generation is intermittent, producing energy only during daylight hours, which can create a gap between energy supply and actual consumption, especially during early morning, evening, or peak demand hours.

This is where battery energy storage systems (BESS) become necessary. By pairing a solar plant with a BESS, cement plants can store excess solar energy during the day and use it when needed, reducing reliance on diesel generators and expensive grid power. This not only smooths out power availability but also allows for peak demand management, cost optimization, and better compliance with renewable purchase obligations (RPO).

UnityESS by Ornate is a Made-in-India, modular energy storage solution designed for industrial conditions. It delivers:

- Reliable power backup for continuous operations

- Optimized energy use to lower electricity bills

- Peak shaving and demand management capabilities

- Scalable deployment, allowing plants to expand storage as their solar capacity grows

For cement plants looking to maximize their investment in solar, UnityESS ensures that the energy generated is fully utilized, cost-effective, and reliable, while also reducing carbon emissions and enhancing sustainability metrics.

In short, Energy Storage Systems turns solar energy from intermittent to dependable, giving industrial consumers a real path to energy security, operational savings, and a cleaner, greener footprint.

Sustainability in Cement Industry

Climate change and energy security are worldwide issues, and the cement industry understands the importance of contributing its fair share as a result of its technological and socioeconomic growth.

Many organizations in this sector are turning to renewable energy to reduce their energy expenses and carbon footprint.

In India, the Ultra Tech group is a prime example. In Feb 2023, Ultratech inaugurated an 8.5 MWp solar plant at their Varanasi production facility. The project would meet a third of the facility’s total power requirement. Moreover, the company is committed to 100% of its electricity requirement through RE sources.

Project Report

Dalmia Cement, Assam

2.24 MW | 135,000 Sq. Ft.

Dalmia Cement, a prominent cement manufacturer in India with a legacy since 1939, is known for its innovative and sustainable practices in the cement and construction sectors as part of the Dalmia Bharat Group.

Dalmia Cement chose Ornate Solar’s advanced InRoof technology to address its energy requirements. Ornate Solar has successfully deployed a 2.24 MW solar roof system across 135,000 sq. ft. of roof space.

Conclusion:

As India’s energy consumption rises owing to industrial and population expansion, meeting the country’s energy needs might become difficult in the coming years. However, with increased focus from the Indian government and business sector on renewable energy sources, particularly solar power plants, reaching the energy objectives would become much simpler.

India’s cement business has a lot of potential in this sector.

There are numerous advantages to installing a solar power plant in the cement industry, including lower solar plant installation costs, higher fuel costs, an indirect effect on PAT as renewable energy power exceeds the boundary limit, the ability to sell E- Certificates if the reduction target is met, and, last but not least, solar power will be a profitable business in years to come.

The government must also play a key role in the sector’s rapid development by providing the required regulatory support, incentives, and tariff plan mechanisms.

Solar Installations at Cement Factories

| S1 No | Energy Consuming Areas | Electrical Energy Consumed |

|---|---|---|

| 1 | Mines, Crusher and Stacking | 18.0 kwh/MT |

| 2 | Reclaimer, Grinding and Transport | 18.0 kwh/MT |

| 3 | Kiln feed, Kiln and Cooler | 22.0 kwh/MT |

| 4 | Coal Mill | 5.0 kwh/MT |

| 5 | Cement Grinding and Transport | 23.0 kwh/MT |

| 6 | Packing Plant | 1.5 kwh/MT |

| 7 | Lighting, Pumps, and Services | 4.0 kwh/MT |

| Total | 75.0 Kwh/MT |

About Ornate Solar

Ornate Solar is India’s leading solar company with 10 years of experience. By partnering with the best-in-class global solar brands, we bring the most reputable solar panels, solar inverters, and solar accessories to you and make your shift to solar cost-effective and easy.

Ornate Solar is also a trusted BESS manufacturer in India. We have developed UnityESS, an advanced energy storage solution to provide reliable power and energy independence. We have developed India’s first Integrated InRoof system- a roof made of solar panels that eliminates the need for sheet roofing.

We deliver across India.

For more information, please give us a call at 1800 2026 252.

Informative and forward-thinking post! Great explanation of how solar supports energy demand in cement. Important for sustainability conversations. Really appreciate the detailed insights!

Interesting information thanks for sharing .Keep up the good work.

Thank you, we are glad that you found our content informative.